Our scope of work for maintenance includes:

1. Fire Alarm System

2. Fire Extinguishers

3. Fire Hose Reel System

4. Fire Pumps

5. Sprinkle System

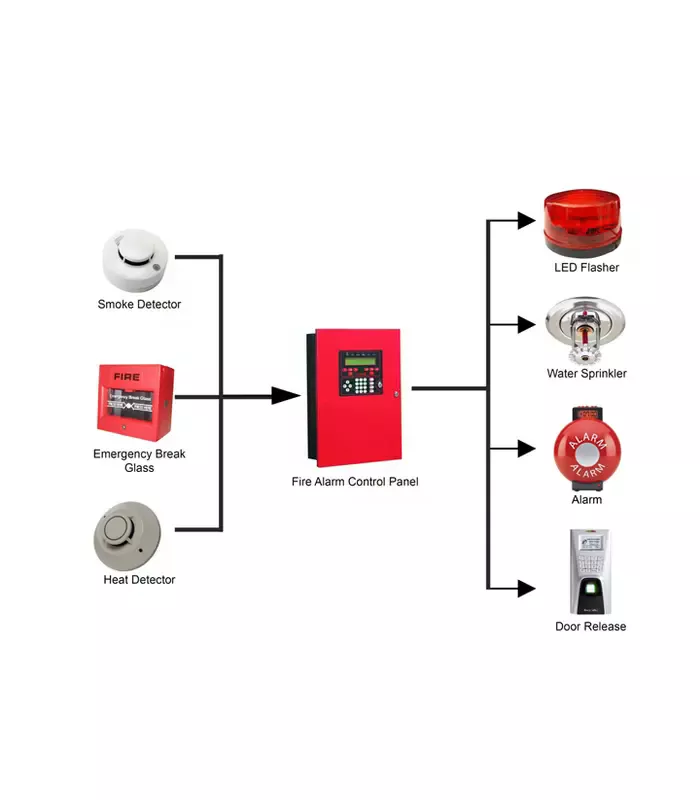

FIRE ALARM SYSTEM

- Conditions of control panel i.e. no physical damage, indicators, intact, etc.

- Check-up batteries and charger operation with or without main supply.

- Checkup of control panel response to alarm condition audibly indications i.e. all bells active on receiving of fire alarm.

- Cleaning of associated devices necessary.

- Testing of 'Alarm receiving Devices' for visible and audible indications in compliance with required standards.

FIRE EXTINGUISHERS

- Extinguishing medium and applied pressure.

- Medical functions of all components.

- Extinguishers are located in designed place.

- A sticker will be fitted to all extinguishers, hydrants indicating the inspection date, and provision.

- The extinguished location will be marked and fitted to all extinguishers.

HOSE REEL SYSTEM

- Clean and check hose reel cabinets. Lubricate the hinges.

- Inspect the swing mechanism of each hose reel unit of lubricant where necessary.

- Run out hose, check for lubricate where necessary. Run out hose, check for damage or deterioration. Check nozzle mechanism.

- Condition of equipment, i.e. no physical damage or corrosion or leakage.

- Discharge water for pressure rating.

- Response to pump, i.e. when operated pump should start automatically.

- Inspection of valves, nozzles

SPRINKLER SYSTEM

- Visual inspection of pump room pipe work, joint and fittings for leakage. Check corrosion and paint work.

- Exercise electric pump, check start sequence.

- Exercise diesel pump, check start sequence and temperature (where fitted), engine speed (where fitted), shutdown mechanism. Check batteries and charger. Check fuel level.

- Annually change oil and filters, controllers' fuses, check pump alignment and coupling condition.

- Check pump motor set, mounting, bearing and leakage.

- Check pressure switch operation, setting, flow switches, pump run timers, system standing pressure and fall back.

- Check and exercise all valves.

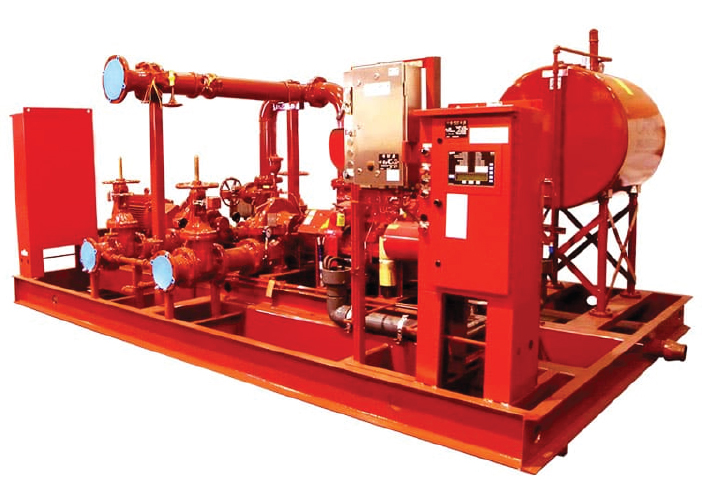

FIRE PUMPS

- Visual inspection of pump room pipe work, joint and fittings for leakage. Check corrosion and paint work.

- Exercise electric pump, check start sequence.

- Exercise diesel pump, check start sequence and temperature (where fitted), engine speed (where fitted), shutdown mechanism. Check batteries and charger. Check fuel level.

- Annually change oil and filters, controllers' fuses, check pump alignment and coupling condition.

- Check pump motor set, mounting, bearing and leakage.

- Check pressure switch operation, setting, flow switches, pump run timers, system standing pressure and fall back.